Host pipe cleaning & inspection

Close-fit Lining Methods

Whilst restoring the internal diameter is not critical for slip lining, it is critical if a close fit or tight fit technique is to be used. The host pipe must be thoroughly cleaned before inserting the liner, and the cleaning process should remove all corrosion products and other debris to restore the original internal diameter, to maximise flow capacity and leave the surface as smooth as possible to reduce friction during insertion.

It is important to ensure that all the host pipe ends are cleanly cut, and without irregular steps, flaws, grooves or cracks, as these will act as stress raisers and could result in the host pipe cracking when the liner pipe becomes a tight fit. The inside circumference of all cut ends must have a generous smooth radius ground on them at exit ends of intermediate excavations, otherwise the liner pipe could become scored or scraped during insertion, possibly then requiring the liner to be removed and replaced.

Once cleaning is completed the host pipe should be subjected to a recorded inspection throughout its length using CCTV and ideally incorporating a laser light ring system. This inspection is not only looking for the cleanliness and surface finish achieved by the cleaning process, but for any areas of pipe wall loss, roughness or protrusion or discontinuity, such as a ferrule or plug, a displaced joint or unrecorded fittings, appurtenances or bends. The laser light ring measures any deformities so the data will also enable the internal diameter of the host pipe to be accurately measured over the entire length for the first time. This is essential for close-fit methods, especially concentric ones, in order that the installer can select the optimum diameter reduction parameters for the project.

For close-fit liners it is important that any sections of the host pipe with an internal diameter less than that assumed in the design process be identified, quantified, and accurately located, as these may compromise the installation by locally preventing full reversion which would result in the liner pipe being more susceptible to collapse under net external hydraulic pressure.

Also for close-fit liners it is particularly important that the host pipe internal diameter is reasonably constant through the entire length of the insertion, as otherwise the recovery process may be compromised. This is especially important in the die drawing method.

Image courtesy: Exova Utilities

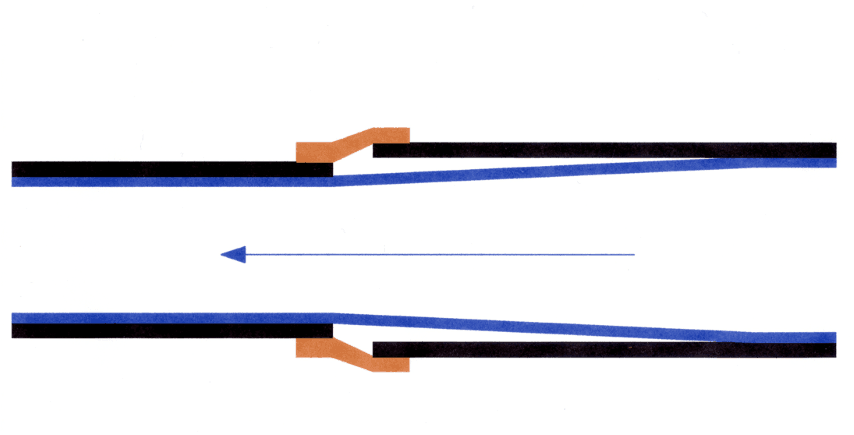

As an example, this diagram illustrates a Die Draw reversion which has started at the die end to the right and is progressing in the direction of the arrow towards the pull end. When it encounters a section of host pipe of a smaller diameter, it becomes a tight fit in that section before recovery can be completed up to that point, and once locked tight in the smaller diameter section, no more longitudinal movement can take place and further diametrical recovery is impossible.

Slip-lining is perhaps the oldest of all trenchless techniques . It involves the insertion of a new PE100 or PE100-RC liner pipe of standard diameter and SDR into an existing pipe. Under the right conditions, slip lining is also the simplest trenchless technique. A new pipe with an outside dimension smaller than the inside dimension of the host pipe is either pulled or pushed into the host pipe. The ideal host pipes for slip lining are straight with no deformities, no or modest bends, no severe protrusions into the pipe, and only modest offset joints.