What is mechanical assembly?

Mechanical assembly requires the use of fittings, generally working on the compression principle, to join different materials together. It is most commonly used with PE for joining the PE to a pipe or fitting of a different material, or in circumstances where fusion is not feasible.

Larger diameter mechanical fittings can include a stiffener which is placed inside the pipe or fitting to ensure stability when the fitting is compressed, but these are generally not required in smaller diameter pipes.

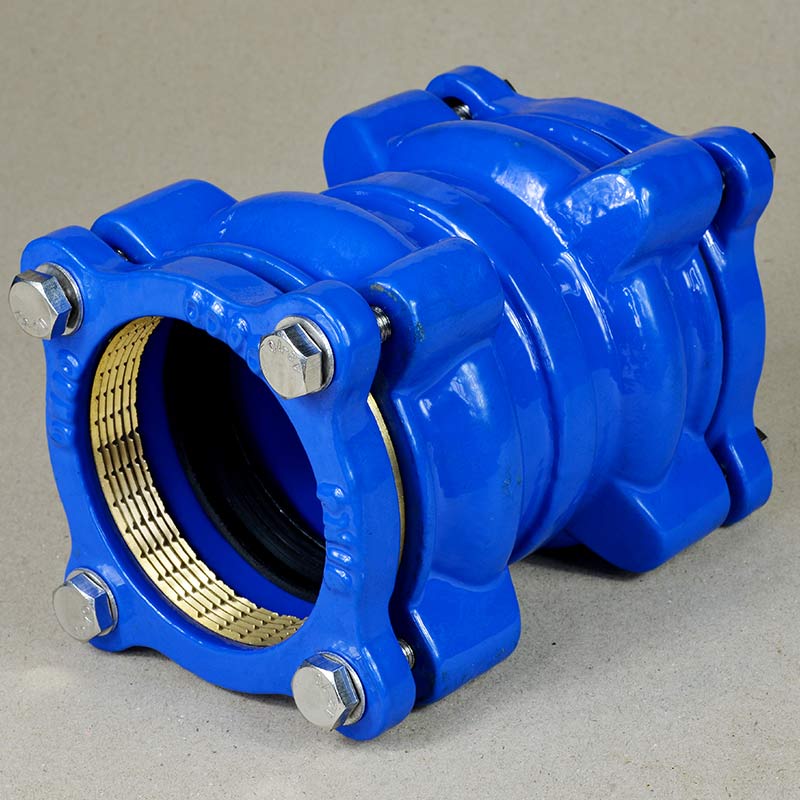

All mechanical fittings that are specifically designed to be used with PE pipes have an arrangement of teeth, ridges or grippers that, when the fitting is tightened up, bite into or grip the outer surface of the pipe, preventing it from being pulled out. Such arrangements are designed so that the fittings are fully end load resistant. This means that they can withstand all the longitudinal forces that are placed on the pipe during operation, for example when a valve is closed. This feature maintains the continuity of the pipe system and removes the need for the use of thrust blocks in the pipeline construction. The fittings also include gaskets which are compressed to effect the seal at the rated pressure of the fitting.

The following images of couplings and a flange adaptor clearly show the ridged arrangement which bites into the pipe surface and provides the restraint.

Examples of metallic mechancial fittings for PE pipe connection

Whilst metallic fittings are always used for larger diameters pipes, corrosion resistant plastic compression fittings are commonly used on pipe sizes of up to 75 mm OD (Outside Diameter), with some manufacturers producing fittings for sizes of up to 110 mm OD. There are many different types of compression fittings available and they are especially useful for connecting smaller diameter PE pipes to pipes made from other materials, which frequently have a different outside diameter, and to other small fittings such as stop taps. Examples are shown below

.jpg)

.jpg)

Tee Elbow

.jpg)

.jpg)

Coupler Stop Tap

Images courtesy Plasson Ltd

In some regions of the world, where smaller diameter pipe networks are more common, compressions fittings, rather than PE or metallic fittings, are used throughout the network, with only the pipe itself being PE. End users need to be aware that many of the plastic compression fittings on the market are meant for use in non-regulated irrigation systems and are not designed for long operational lifetimes. It is therefore essential that all fittings used in long term projects are tested and certified in accordance with ISO 17885:2021. Similarly the manufacturer's recommendations on installing the fitting, including any limitations on torque to be applied in tightening the fitting, should be followed at all times. There are often restrictions on the use of mechanical fittings in gas networks, where fusion jointing is preferred in order to minimise the risk of leakage. Where mechanical fittings are permitted they will have internal supports to avoid creep of the pipe which can lead to leakage. Some end users in the gas industry specify mechanical fittings without elastomeric seals, in which tightness is achieved by compression of the PE pipe to the fitting body or stiffener. The fittings for use in gas and water can differ and it is essential to use the correct fitting for the application. If there is any doubt the manufacturer of the fitting should be contacted.

References

ISO 17885:2021 Plastics pipes and fittings - Mechanical-joint compression fittings for use with polyethylene pressure pipes in water supply systems.