Introduction

This design module will guide the designer through the process of selecting the appropriate PE rehabilitation methods for a project. It sets out and explains all of the things of which the designer needs to be aware and consider, and presents these in a logical and chronological manner so that whilst nothing should be overlooked, a satisfactory design can be offered to the decision module, whilst avoiding unnecessary work. It is primarily a guide and ‘aide memoire’ not a design programme or procedure, and where equations are included, these are simply examples to make the guide easier to follow.

Classes of Lining

There are 4 classes of rehabilitation lining for pressure pipes, defined in ISO11295 and AWWA Manual M28. This Guide will use the ISO11295 classifications: A-D.

.png)

The PE100 & PE100-RC trenchless lining methods are all either Class A or Class B.

|

PE100/PE100-RC Class A |

PE100/PE100-RC Class B |

|

Sliplining |

Close-fit lining with thickness/SDR sufficient for hole and gap spanning at full internal operating pressure but not sufficient to resist this operating pressure and external buckling load without external support. |

|

Close-fit lining with thickness/SDR sufficient to resist full internal operating pressure and external buckling load. |

Setting the design parameters

At the start of the design process, it is necessary to establish the basic operating parameters, namely the capacity or quantity that the pipe will be required to deliver, the hydraulic gradient available to perform the delivery, and the pressure to which the pipe will be subjected in service.

Only two input parameters are necessary in order to use the decision model :

-

The pipe internal diameter necessary for the flow capacity required. This can be designed using the Hazen-Williams formula below.

-

To know the maximum operating pressure on the pipeline.

It is important that the capacity parameter is sensible and realistic, as there is often an unjustified reluctance to downsize. Certainly, any decision to upsize should be based upon reliable predictions of increased demand, as oversizing can result in stagnation and consequent water quality issues, as well as increased costs. On the other hand, downsizing can result in water shortage and negative system pressure with potential for contamination, under emergency fire demand. This should be carefully considered, even for countries where fire demand supply is not mandatory. Finally, if possible, a degree of latitude should be agreed, as when it comes to the final choice of technique, a considerable saving may sometimes be made if a relatively small reduction in capacity can be accepted.

What size pipe is required?

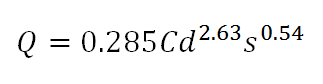

Having decided upon the required capacity and the hydraulic gradient available, the first step in determining the size of pipe required is to calculate the internal diameter. This can be obtained by inputting the capacity Q, friction coefficient C or roughness factor k, and hydraulic gradient s into one of the relevant flow equations, such as Hazen Williams or Colebrooke White, solving for internal diameter d. As PE is extremely smooth, the friction coefficient C for Hazen Williams is generally taken as 150, and the roughness factor k for Colebrook-White 0.00152 mm.

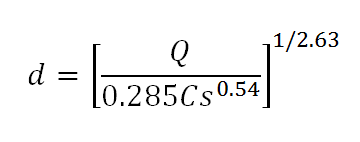

For example, this is the Hazen Williams flow equation arranged to solve for d:

Because PE pipe is produced using an extrusion process, nominal pipe diameters DN refer to the external diameter, and pipes are manufactured in a series of standard metric sizes, each size generally available in several standard pressure ratings, resulting in different wall thicknesses for different pressures. The relationship between the external diameter and the wall thickness is known as the Standard Dimension Ratio or SDR and is simply the ratio of external diameter to wall thickness. The most common SDRs and their pressure ratings are:

|

SDR PE100/PE100-RC |

MOP Gas (bar) |

MOP Water (bar) |

|

9 |

15.6 |

20 |

|

11 |

12.5 |

16 |

|

17 |

7.8 |

10 |

|

21 |

6.25 |

8 |

|

26 |

5 |

6.4 |

|

33 |

3.9 |

5 |

Note that SDR33 should only be used as an interactive lining pipe, and not as an independent pipe. Ratings for pressure sewerage are the same as for water.

Having decided upon the pressure to which the pipe will be subjected, the appropriate SDR can be selected, and the second step in determining the size of pipe required is to choose the nominal pipe size DN that has an internal diameter closest to, but not smaller than, the internal diameter d determined in step one. This pipe will be a nominal standard size DN and SDR, with the benefits of being readily available as a stock item, at least in the small to medium ranges, as well as having a standard range of fittings available, this latter having substantial cost saving implications.

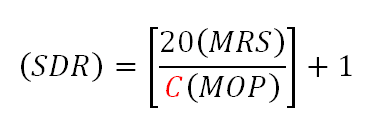

The range of standard SDRs is calculated using a service coefficient C, not to be confused with the friction coefficient C used in the Hazen Williams flow equation. The default value for water and pressure sewers is 1.25 and for gas 2.0. This is simply a safety factor to accommodate any site or operational factors that might effect the performance of the pipe or shorten it’s life. If there are any other relevant factors such as temperature, the chemistry of the fluid to be carried or the surrounding ground, then the value of C can be increased accordingly, and the appropriate SDR calculated using the equation:

where (MRS) is the minimum required strength of the lining pipe material in MPa, and (MOP) is the maximum operating pressure in bar. For PE100 and PE100-RC the MRS is 10 MPa.

The UK IGN 4-32-18 gives guidance on temperature related de-rating, and particular care should be taken when lining pipes operating above ground in climates with large temperature variations, due to the large difference in the coefficient of thermal expansion between PE and metallic host pipe materials.

Will it be possible to line the existing main?

The primary requirement of network operators is the hydraulic capacity of the pipes. This is a function of their diameter and friction co-efficient. It may be possible to satisfy the required hydraulic capacity parameters by sliplining, simply inserting a nominal standard DN and SDR pipe inside the existing main. In this case the SDR will be that for the MOP of the pipeline as set out above.

If not, it may still be possible to satisfy the required hydraulic capacity parameters by close fit lining the existing main, and here any latitude agreed on the required capacity when initially setting the design parameters could have substantial cost saving implications.

For any lining technique other than slip lining, it is necessary to reliably establish the condition, internal diameter, and residual strength of the existing main, and this can be done without taking the main out of service by using under pressure tapping to remove coupons for metallurgical testing and inserting CCTV equipment, and undertaking ultrasonic or electromagnetic scanning of the main, either externally at various locations along its length or internally along its full length.

In the case of close fit Class A lining, the external diameter of the lining pipe is fixed by the internal diameter of the main to be lined, and the appropriate SDR is then applied to find the internal diameter of the lining pipe, from which the available hydraulic capacity can be obtained from one of the flow equations used in the first step, now solving for quantity Q.

Such a pipe of non standard DN and SDR will potentially cost more, as the manufacturer has to reconfigure the extrusion line, and non standard fittings will be required. However if for instance the maximum operating pressure is only around 12bar, then the selection of an SDR of 13 rather than 11 would use less PE, and on a large diameter and long pipeline, could result in large savings.

What about an interactive lining?

If it is not possible to satisfy the required parameters using a close fit independent lining, and if the existing main is structurally sound, then it may still be possible to satisfy the required parameters by inserting a Class B interactive lining. In such a case, the lining pipe is simply required to span perforation leaks, holes and gappy joints, and it may be possible to use an SDR of 40 or more depending upon the size of the leaks and gaps to be spanned. Also, as an interactive liner will require substantially less PE and maximizes the hydraulic capacity, it is always worth considering, even if the required hydraulic capacity parameters can be satisfied using an independent lining.

A further practical benefit of interactive liners is that they require less pulling load for insertion than independent liners thus smaller winches can be used. This can be important in city centre locations where working space may be limited.

.png)

P = (D/d)2 x 5.33/(DR-1)2 x (σ/N)

σ = long-term allowable PE stress (MRS)

D = Inside diameter of the host pipe

DR = the maximum Dimensional Ratio of the PE liner pipe

The above equation can be solved to determine the maximum DR and thus the minimum thickness of the liner. Typically a hole diameter d of 50mm is used for design unless a different size is specified.

Note that PE100 pipes are normally manufactured at Standard Dimension Ratios (SDRs) such as SDR11, SDR17, SDR26 and SDR33. Designers should ensure that the SDR of the PE100 liner pipe being used for the installation is no higher than the DR (Dimension Ratio) calculated using the above equation.

Completely dislocated joints or circumferentially cracked pipes must not be treated as gaps when considering an interactive lining pipe, and in such cases an independent lining pipe is essential.

Also, there will be times when a main is out of service and empty, and at such times the liner may be subjected to a net positive external pressure due to ground water, and the liner must have sufficient ring stiffness to avoid collapse. This may well require a lower SDR than that necessary to just span voids and gaps.

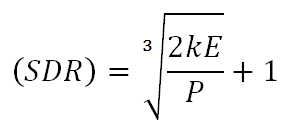

Lining pipe collapse in such circumstances will be by buckling, and in the case of a close fitting lining pipe, resistance to unrestrained buckling is enhanced by the degree of tightness of the fit by a factor k which has a value of 7 for a perfect fit, but generally less than this for the sort of fit expected in practice. The critical SDR at which buckling may occur can be calculated by inputting the flexural modulus E and the potential maximum external pressure P plus an appropriate safety factor, into a ring stiffness equation:

For example, here arranged to solve for (SDR)

It is very important that in determining the potential maximum external pressure that can be exerted during ‘empty main’ situations, the topography along the route is examined. In hilly terrain, water may enter the host pipe/lining pipe interface annulus at a high point, thus subjecting the lining pipe at a relatively low point to a head in excess of the actual water table at that low point. Even in service, the lining pipe may experience net positive external pressure during surge conditions, and in deciding whether to use short term or long term flexural modulus in the design, it should be remembered that negative surge pressure pulses can be measured in minutes rather than seconds when dealing with long mains of large diameters, whilst ‘empty main’ situations can last for months rather than hours.

External load resistance

It is necessary to consider carefully whether external loads from live (traffic) loading, soil load and ground water pressure need to be supported by the PE pipe or liner.

Where there is no host pipe as may be the case in trenchless new installation, pipe bursting and Class A lining, this load must be supported by the PE pipe or liner. Where there is a host pipe, for example in trenchless new installation within a casing casing pipe, the external loads are carried by the host or casing pipe. In sliplining, despite there being a host pipe the liner may need to be designed to support the external loads in case the host pipe deteriorates.

However, unlike the conditions where a pipe is newly laid by open cut, and is subjected to substantial forces both during and after reinstatement, PE pipe for new trenchless installation when direct buried is installed into ground that has been in equilibrium for many years. As the ground around the small annular space created during installation relaxes and comes into contact with the pipe, the pipe will only be subjected to a small symmetrically applied radial force. It is however always prudent to check that no particular site conditions exist that might alter this, and if so, to use one of the design procedures for flexible pipe, and if necessary select a lower SDR to provide sufficient ring stiffness to prevent failure if asymmetric loading is considered to be possible and significant.

Flexible pipe design procedures must always be applied if piecing up with PE, as these are inevitably open cut, and similar consideration should be given to pipes in infrastructure congested locations, where third party excavations are likely to create open cut conditions.

PE100 Pipe - Properties and Types

Follow this link to "Properties and Types" section

Decision Module

To evaluate your projects suitability for a trenchless PE100 pipe installation, please follow the link below.

Top articles

PE100+ position letter on ANPT

(SCG) resistance on pipes for pressure applications since many years. With the introduction of PE 100-RC materials in EN 1555, EN 12201 and ISO...

PE 100-RC+ Quality Materials List

PE 100-RC+ materials have become an essential and well established sub-family of PE 100 compounds. They have a higher stress crack resistance and...

PE 100+ association leads permeation tests for H2 ready certification

A number of gas utilities and grid owners have approached the PE 100+ association regarding the suitability of PE 100 pipe systems for the...

Why choose PE compounds for pressure pipe ?

Simplicity or consistency There are two approaches to PE100 pipe manufacture: Fully compounded. The polymer producer manufactures and supplies to...

PE100+ Quality Materials List

PE100+ Quality Materials List is valid until 31st of March 2026. It is available online and a PDF version can be downloaded at the bottom of this...

Testing methods

Creep rupture strength - Internal pressure test Constant internal pressure at constant temperature The internal pressure test is standardised in ISO...

Pipe Reaming

PIPE REAMING - TECHNIQUE Pipe reaming , also known as pipe eating , is a trenchless pipe replacement technique that removes the host pipe while at...

Pipe Bursting and Splitting

PIPE BURSTING / SPLITTING - TECHNIQUE Pipe bursting and pipe splitting are trenchless methods used to replace existing pipelines with PE100 or...

What range of pipe dimensions is available?

PE100 can be manufactured in a wide range of polyethylene pipe diameters from 16mm to 2000mm. Even larger diameters are possible with the...