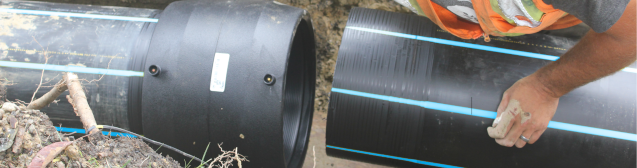

What is electrofusion?

Electrofusion Jointing

Electrofusion is a simple method of joining PE pipes in circumstances where butt fusion is not practicable. In addition to the jointing of line pipes using couplings this can be where fittings such as valves, elbows, and tees must be added. Prefabricated fittings are used, incorporating an electrical heating coil which melts the polyethylene of both the fitting and the pipe, causing them to fuse together when the material cools.

How does electrofusion work

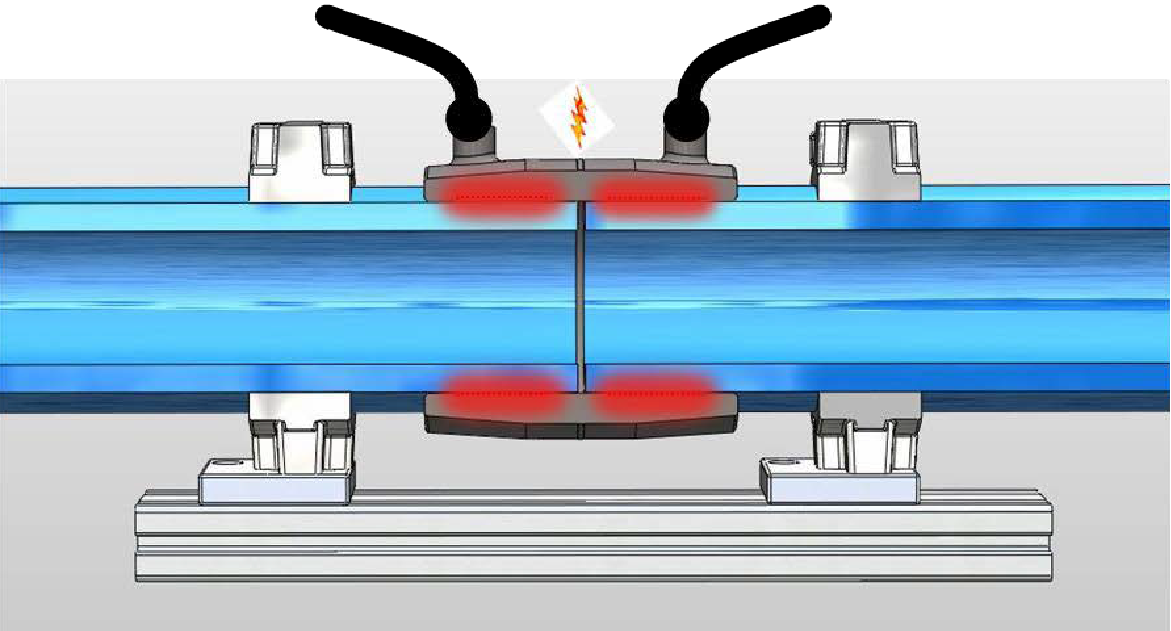

Diagram of electrofusion coupler. Image courtesy Plastics Pipe Institute

The characteristics of the fitting to be welded, such as the fusion time, are registered via a barcode on the fitting. An electrofusion control unit (ECU) supplies the electrical energy necessary to heat the coil. When the coil is energised, the material in the fitting adjacent to it melts and forms an expanding pool which comes into contact with the surface of the pipe. The continued heating causes the pipe surface to melt and a mixing of pipe melt and fitting melt takes place; this is vital to produce a good weld. Following the termination of the heat cycle, the fitting and the pipe are left to cool and the melted material solidifies to form a sound joint.

Hot and cold zones, sometimes called fusion and freeze zones or a combination of the two names, are formed after energising the coil. The length of these zones is particularly important. Each zone ensures that fusion is controlled to a precise length of the fitting socket and that sufficient melt pressure is generated and applied throughout the jointing process. The precisely controlled pitch and positioning of the coil in relation to the inner surface of the socket ensures uniform heat distribution.

.png)

Diagram of electrofusion coupler. Image courtesy Fusion Group Ltd

The basic fusion parameters: temperature, pressure and time, are controlled by the ECU which is programmed to establish these parameters from the barcode read from the fitting itself. The ECU also provides a permanent record of the procedure followed.

How to ensure effective electrofusion

In addition to the

electrofusion process itself, the effectiveness of an electrofusion joint also

depends on the rerounding of the pipes if they have taken on a distorted or

oval shape, preparation of the joint surfaces, correct alignment of the pipes

and fitting and ensuring that no movement takes place during the fusion

process.

Rerounding of pipes

Pipes that are distorted

or that have taken on an oval shape need to be rerounded to ensure that they

will fit in the electrofusion fitting and that the annulus between the pipe and

socket is the same all the way round. In the case of large diameter pipes this

may require the use of hydraulic rerounding equipment. For small and medium

diameters, the restraining and alignment clamps that are used to hold the pipes

in place during the electrofusion process are normally sufficient for the

rerounding of the pipes to the required degree.

Preparation of the joint

surfaces

The entire pipe surface that

will be inserted into the electrofusion fitting must be peeled or scraped with

an appropriate tool, as recommended by the fitting manufacturer. It is strongly

preferred that a peeling tool is used rather than a hand scraper, as this

ensures that all of the pipe surface is removed to a depth of approximately

0.2 mm. This is sufficient to remove any oxidised, dirty or contaminated

material. Whilst more time consuming to use than hand scrapers, pipe peelers

provide a far more consistent removal of the pipe surface that is to undergo

electrofusion. Hand scrapers are however useful for the end preparation of the

pipes. Other equipment such as metal files, rasps, emery or sand paper should

not be used.

After peeling, the peeled

surface must be wiped with an authorised Isopropanol impregnated pipe wipe, as

recommended by the pipe or fitting manufacturer, to remove any dust residue.

Methylated spirits, acetone, methyl ethyl ketone (MEK) or other solvents should

not be used for wiping the scraped surface as they can leave a residue that

will interfere with the fusion process. The prepared surfaces must be

completely dry before proceeding.

The electrofusion

fittings themselves should remain within their protective airtight plastic

packaging until just before the prepared pipes are to be inserted in to the

fitting. This is to prevent any contamination of the fusion surface. If the

interior of the internal surface of the fitting should somehow be contaminated,

it should be thoroughly cleaned with Isopropanol impregnated pipe wipes and left

to dry prior to the pipes being inserted.

Use of pipe restraining

and alignment clamps

As the name suggests,

such clamps are used to ensure that the pipes and electrofusion fitting are all

correctly aligned prior to commencing the fusion process and are then firmly

held in that position until the end of the complete fusion process. Whilst the

ECU can be carefully disconnected from the fitting once the heating phase of

the process is complete, the clamps must remain in place until the end of the

cooling phase. This is to ensure that the polyethylene that was melted during

the heating phase has cooled and set hard within the fitting. At the end of the

heating phase, the ECU should inform the operator of the required cooling time.

Alternatively the cooling time should be either marked on the fitting or given

in the documentation that comes with the fitting.

The resulting joint, when

properly made, is at least as strong as the original pipe and can withstand all

the loads applied during routine installation and operation.

Manufacturers of electrofusion fittings often publish technical guidance on their use. An example of a good guidance document with helpful images is the one provided by Radius Systems:

Electrofusion-Jointing-Guidance.pdf (radius-systems.com)

References

ISO 12176-2:2008 & Amd. 1:2021 Plastics pipes and fittings - Equipment for fusion jointing polyethylene systems - Part 2: Electrofusion

Related keywords : electrofusion, fusion pipe, pipe fusion, electrofusion welding, electro fusion welding, socket fusion welding times, fusion welding definition, fuse pipe, plastic gas pipe welding, what is electric fusion welding, electrofusion welding procedure, plastic pipe fusion, fusing plastic pipe, electrofusion hdpe, hdpe electrofusion welding, electro fuse, methods of joining pipes, pe plastic pipe, joining poly pipe, electro fusion joint, hdpe pipe electrofusion welding, electrofusion scraper tools, electric fusion welding pipe process, forming hdpe with heat, hdpe electrical pipe, hdpe fusion couplings, electro fusion joint hdpe, hdpe solvent weld, hdpe pipe scraper tool, hdpe pipe welding procedure, hdpe electrofusion fittings