How can I verify the grade of PE used to manufacture the pipe?

National and International standards require that the pipe is clearly marked with the grade of PE from which it is manufactured on the outer surface of the pipe along with other information including: manufacturer's name or trade mark; pipe diameter; pressure rating; and date, and a code, related to manufacture. This information allows traceability through the pipe manufacturer's Quality Assurance system to determine further details of the raw material used, should that become necessary.

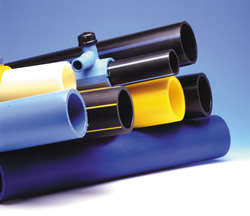

Additionally, for specific applications, e.g. gas and potable water distribution, some standards require the pipe to be manufactured within a specific colour range to differentiate from pipes intended for other applications. Typically the colours are:

| Gas: | Yellow pipe Black pipe with yellow stripes |

|

| Water: | Blue pipe Black pipe with blue stripes |

Traceability is an integral part of modern, sophisticated, Quality Assurance systems used for PE pipe networks. The systems available, and mandatory at many end-users, enable tracing through the whole process, from the resin batch at the PE producer, through pipe extrusion, the utility company and the installation contractor's operations. All installations can be traced back to the resin batch from which they were produced, with full data on the history of the pipe or fitting at any location.

The most up-to-date traceability systems are based on the use of barcodes. The barcodes can record data covering:

- fusion-jointing equipment data

- fusion-jointing equipment operator data

- site data (geographical location)

- data on fittings and pipes

- fusion-jointing parameters

- installation dates

- assembly procedures

This information on the barcodes can be affixed to the pipes and fittings insitu, and recorded in a database, ideally linked to a Geographical Information System (GIS). At any subsequent excavation or operation the barcode can be read and all data on the pipes and fittings concerned can be accessed. Similarly in planning operations and works the data is readily accessible from the GIS or database.

References

ISO 4437:2007 Buried polyethylene (PE) pipes for the supply of gaseous fuels - Metric series - Specifications

ISO 12176-4:2003 Plastics pipes and fittings - Equipment for fusion jointing polyethylene systems - Part 4: Traceability coding

Gueugnaut, D. Mise en place de la traçabilité; l'exemple des conduites de gas en polyéthylène à Gaz de France. Gas, Wasser, Abwasser (GWA); SVGW Zürich, October 2003.

|

|

|

| Pipe colour schemes (Borealis, INEOS Polyolefins) | |